Scanning Electron Microscopy (SEM)

SEM functioning and samples preparation

Before really starting experiments on our foams, we wanted to know what their microstructure was. We decided to observe them under a scanning electron microscope (SEM).

SEM functioning:

The observed sample is scanned by an electron gun (features of the electron gun: tungsten filament, acceleration voltage around 10-15 kV). During an observation, several signals are passed on and transformed in electric signals collected by a detector. The image is created by reflection, which distinguishes this microscope from others which give a simultaneous image of the set of object points using lens.

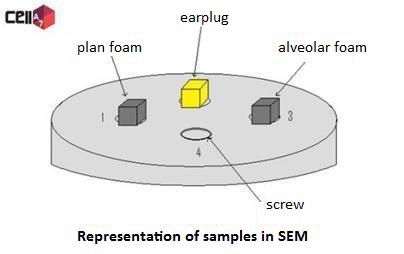

Samples are put on screws which enable electrical contact in microscope. Number one is put at the bottom to keep the same point of reference for each observation.

However, SEM has limits and we must consider that the sample must support a high vacuum and conduct electrons. So, it must be conductor. In our cases, polyurethane foams are not conductor, therefore we need to make plating on our samples to obtain a good quality image.

Samples preparation:

Sample preparation is an important step. We cut out small cubes with a side length of about 3 mm with caution in order to not flatten them.

Samples are carefully put on aluminium conductor platforms thanks to an adhesive tape made by an adhesive polymer and carbon which are also conductor. We must not touch them to do not grease them; it is why we use pliers. Samples have also to be numbered to have a good traceability.

Then support and samples are put in the chamber of metallizers where a primary vacuum is made. An argon gas (generator of purple plasma) is injected and a second vacuum is made. These several steps enable a good total clean-up of the chamber.

During metallisation, electrons are extracted from a silver plate present in the chamber by the plasma thanks to a potential difference between bottom and ceiling of the chamber. A fine silver coating appears (thickness of one or two silver atoms) on the foam samples.

Two steps of metallisation of one minute each and with a high voltage are made. This treatment is long because of the nature of samples which have an important porosity.

We stop vacuum and samples are prepared for SEM analysis.

The main interest of this metallisation is to make foam samples conductor to observe them under a SEM which seems not possible without this coating. We know that the treatment has been efficient if we can obtain good pictures of samples.

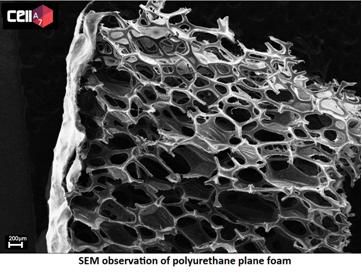

Polyurethane plane foam

We can see that cells are closed as for the other polyurethane foam. Its average size is 330 μm. Observation of the waterproof surface allows us to say that it is a coating which gives it its properties and not a reaction between cells that already exist. This surface has a thickness of 20 µm.

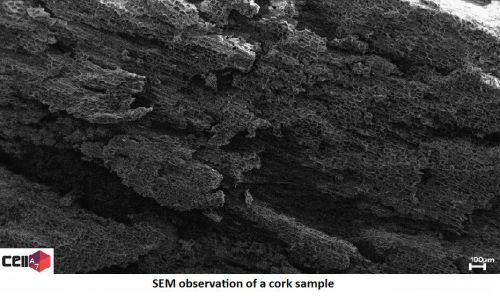

Corks and synthetic plugs

The sample observed has been removed from the internal of cork in transversal direction. Structure reminds of honeycomb cells. Their average size is 32µm.

Comparison with synthetic plugs:

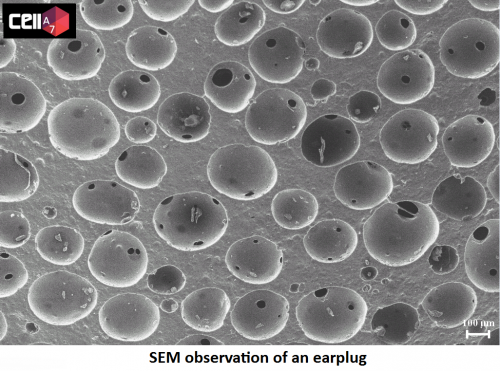

In both cases, we notice that cells are closed. Beige plug has been too damaged during its preparation, we cannot exploit the picture. Red plug is also damaged but it seems that its cells form tubes.

We notice that in different directions layout of cells are different. We can conclude that these three kinds of plugs have anisotropic structures.

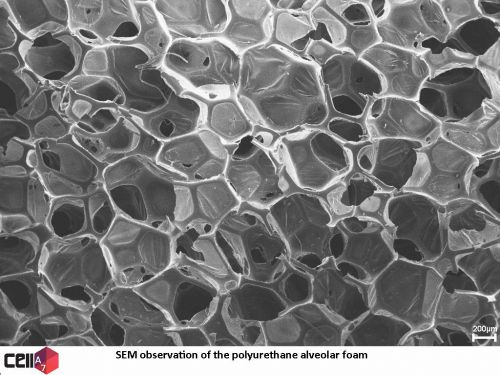

Polyurethane alveolar foam

First, this polyurethane foam has a specific macroscopic structure due to alveolus on its surface. It is a sponge structure. Thanks to SEM, we see that cells are polyhedrons quite isotropic. They are closed and their average size is about 500 µm.

Earplug

On pictures of earplug