Mechanical

Compression tests

We wanted to characterise our materials from a mechanical point of view. We decided to make compression tests on samples of our materials.

These tests involve applying force on a sample in order to have access to specific properties of its mechanical performance such as Young modulus.

For foams, earplugs and cork (in transversal direction), we cut samples in order to have representative volume that is more than 10x10x10 cells or cavities. We made parallelepipoids of foam and cork (in transversal direction) and a cylinder of earplug whose section we consider constant. It is important to cut samples from the internal of materials in order not to take into account edge effect.

For corks studied in longitudinal direction we tested cylindrical samples that are the plug itself, with different solicitation speeds. We also tested corks in transversal direction with different speeds.

You can see below samples cork (transversal direction) that we have tested.

We carried out these tests after adjustment of compression machine and especially zeroing which corresponds to the time when the base and the head of machine are in contact. In this way, we can know the height of sample.

Compression machines may take time to reach the imposed stress. In this case, we observe a compression stop. It can be explained because we study po

rous materials, therefore they contain a lot of air so we have to wait for every layer of cells to be bent.

We must be cautious regarding tests precision because sensors are perceptible in this range of stress. Indeed, tested foams are less resistant than materials considered during the design of the machine.

At the end of test, we have access to the applied force, to time and to lengthening. Thanks to this data, we can deduce the stress σ (σ = F/S) and the strain ε (ε = (l0-l)/l0). During decompression of sample we can determine Young modulus E which is the slope of the curve σ=f(ε). We use about thirty points to calculate it.

There are differences between the different measures and they are sometimes important. In order to know deviation of these values and to increase reliability, we should do more tests to limit uncertainties.

Corks

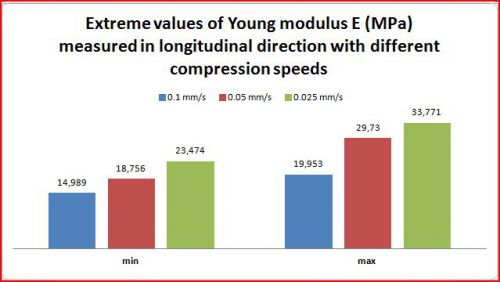

We made nine tests on cork plugs in longitudinal direction at different speeds in order to know if this material has the same performance depending on the speed. A tenth test has been made because we had a problem during a test and we could not exploit it.

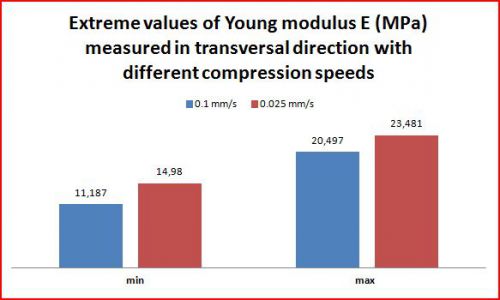

Then, we made six tests on corks in transversal direction with two different speeds to study the influence of direction sample and of speed.

We notice that for corks in the two directions Young modulus are different according to the speeds; corks have properties which depend on compression speed. We cannot conclude on the influence of the direction sample because values are too closes. We should use sensors adapted to this kind of materials.

Even if values are different, this difference is acceptable especially for a natural material.

Polyurethane alveolar foam

We made two tests on two different polyurethane alveolar foam samples.

|

samples : |

E (kPa) |

E (MPa) |

|

sample n°1 |

154 |

0,154 |

|

sample n°2 |

169 |

0,169 |

We notice that for this polyurethane foam values are close. To have more reliability, we could make more tests.

Polyurethane plane foam

We obtained for this polyurethane foam one value of Young modulus: E = 119 kPa = 0,119 MPa.

For this foam we cannot conclude on reliability of this value because we made only one test. However, we notice that it is close to value of the Young modulus of the other polyurethane foam.

Earplug

We made two consecutive tests on the same sample of earplug.

|

E (kPa) |

E (MPa) |

|

BAB 1st test |

257 |

0,257 |

|

BAB 2nd test |

483 |

0,483 |

We notice that for the same sample, Young modulus values are different for the two tests. This difference can be explained because earplug gets back to its initial shape after a while contrary to the other foams. Its performance is called viscoelastic. Then, Young modulus is measured during this step, difference between values are important. In order to make a repeatable test, we should wait more before starting the second compression.