Introduction

After having chosen to study foams, and focused on their acoustic properties, we looked for experiments in order to characterize them.

As the ENSIACET is not equipped to do acoustic measurments, we first contacted the acoustic laboratory called P.H.A.S.E (Physique de l’Homme Appliquée à Son Environnement) to help us, but they never answered.

Then, we asked the IUT of applied physics and insturmentation of Paul Sabatier University in Toulouse which gave us a positive answer. Thanks to the teacher responsible for the acoustic lecture, we got the chance to realise tow acoustic experiments on our foams. Hence, we were able to determine and compare their absorption coefficients.

Acoustics’ basics

For a better comprehension of our experiments and results, here are some simple basics of acoustics.

What is a sound?

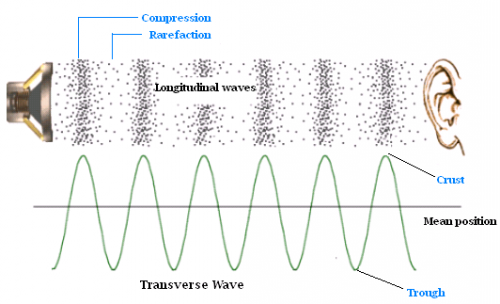

A sound is composed of vibrations transmitted through an elastic solid, liquid or gas, with frequencies in the approximate range of 20 to 20,000 hertz, capable of being detected by human organs of hearing. A sound wave travels through the air or another medium making a pressure variation.

That is what happens when we speak. Our vocal cords vibrate and generate a high and low pressure variation in the air. The sound spreads in air at a speed of approximately 344 meters per second. Habitual speech average fundamental frequency ranges in 75–150 Hz for men and 150–300 Hz for women. Human ear can hear sounds with frequencies of vibration between 20Hz and 20000Hz.

Behavior of a sound wave

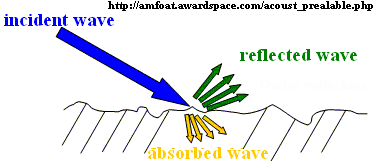

When a sound wave reaches an obstacle, four differents phenomenon happen, as described below :

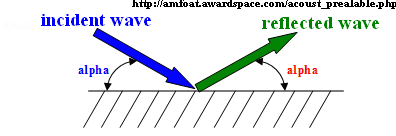

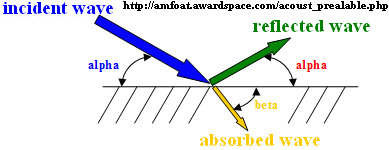

- Reflection

A part of the wave is reflected by the obstacle, we call that echo or reverberation. A soundproof material has a surface made to reduce the reflection or to select useful reflections and unwanted ones.

- Transmission

A part of the incident sound wave is transmited through the mater. This is the phenomenon called acoustic isolation that makes a room soundproofed.

- Absorption

A tiny part of the incident wave is transformed in mechanical energy and in calorific energy. It occurs essentially at the surface of the obtacle. The angle beta depends on the material's preperties (absoption coefficient and thickness) and on the wave frequency.

- Diffusion

If the obstacle's surface is not smooth, the incident wave is reflected in several smaller waves. each bump is acting as a different wall for the sound wave.

Why does a porous material absorb better?

By reaching a porous material, the sound wave can easily enter in it. It generates friction between the wave and the matter, moving light fibers, and making the cinetic energy transformed in mechanical and calorific energy. The porosity must be open, that means that the cells are conected to each other ( ex: foam, glass wool).

The absorption coefficient is weak for low frequencies, and high for high frequencies. Low frequencies absorption depends on the thickness of the material and on its pores or cavities side.

With all this information we can explain why cellular material had been used in the school and what are their utility and their shape.

If this article interests you, please find further information on this website (French website)

==> http://www.lafontaudio.com/criteres.htm

Acoustics in building trade

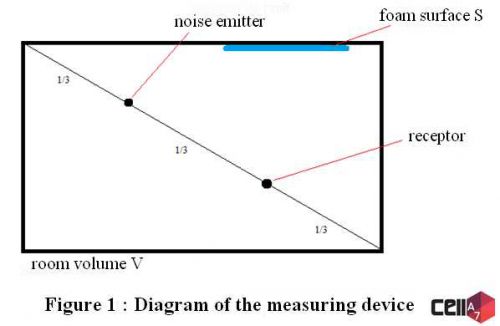

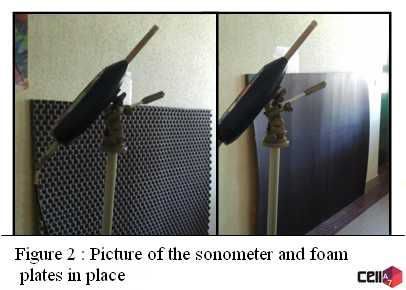

For this experiment, we use a sonometer which record the reverberation time of a sound wave in an empty room with a known volume. The emitter broadcast a specific sound, called "bruit rose" in French, which is used as a known reference. The transmitter and the receiver are set up on the diagonal of the room (one third appart). The foam is placed against one of the walls as shown on the figure below.

It’s important to have an empty room to get the most accurate result as possible. Only one operator stays in the room during the measurment to avoid disturbance.

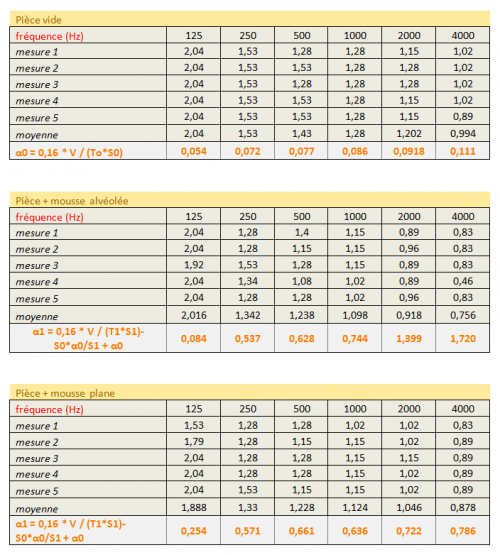

Three successions of five measurements are made : one for each foam and one another without foam (empty room).

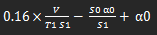

The equivalent absorption area of the room without foam is :

The equivalent absorption area of the room with foam is :

A =  = S0 x α0 + S1(α1- α0) ==> α1 =

= S0 x α0 + S1(α1- α0) ==> α1 =

So, for a volume of the room V = 80m3, a surface of the room S0= 116m2 and a foam surface S1 = 1.8*1.4 =2.52 m2, we get this results :

Which gives :

The absorption coefficient increases when frequencies increase, and it is more important for the flat foam than for the alveolated surface one, considering low frequency. However, for high frequencies (> 1000Hz), the results are reversed.

This shows that cellular materials have many properties which justify their use in the building trade isolation sector.

Compression tests

We wanted to characterise our materials from a mechanical point of view. We decided to make compression tests on samples of our materials.

These tests involve applying force on a sample in order to have access to specific properties of its mechanical performance such as Young modulus.

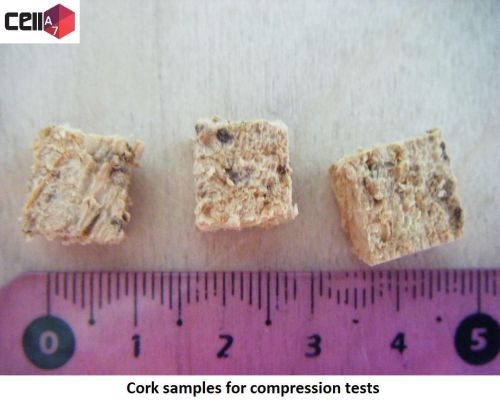

For foams, earplugs and cork (in transversal direction), we cut samples in order to have representative volume that is more than 10x10x10 cells or cavities. We made parallelepipoids of foam and cork (in transversal direction) and a cylinder of earplug whose section we consider constant. It is important to cut samples from the internal of materials in order not to take into account edge effect.

For corks studied in longitudinal direction we tested cylindrical samples that are the plug itself, with different solicitation speeds. We also tested corks in transversal direction with different speeds.

You can see below samples cork (transversal direction) that we have tested.

We carried out these tests after adjustment of compression machine and especially zeroing which corresponds to the time when the base and the head of machine are in contact. In this way, we can know the height of sample.

Compression machines may take time to reach the imposed stress. In this case, we observe a compression stop. It can be explained because we study po

rous materials, therefore they contain a lot of air so we have to wait for every layer of cells to be bent.

We must be cautious regarding tests precision because sensors are perceptible in this range of stress. Indeed, tested foams are less resistant than materials considered during the design of the machine.

At the end of test, we have access to the applied force, to time and to lengthening. Thanks to this data, we can deduce the stress σ (σ = F/S) and the strain ε (ε = (l0-l)/l0). During decompression of sample we can determine Young modulus E which is the slope of the curve σ=f(ε). We use about thirty points to calculate it.

There are differences between the different measures and they are sometimes important. In order to know deviation of these values and to increase reliability, we should do more tests to limit uncertainties.

SEM functioning and samples preparation

Before really starting experiments on our foams, we wanted to know what their microstructure was. We decided to observe them under a scanning electron microscope (SEM).

SEM functioning:

The observed sample is scanned by an electron gun (features of the electron gun: tungsten filament, acceleration voltage around 10-15 kV). During an observation, several signals are passed on and transformed in electric signals collected by a detector. The image is created by reflection, which distinguishes this microscope from others which give a simultaneous image of the set of object points using lens.

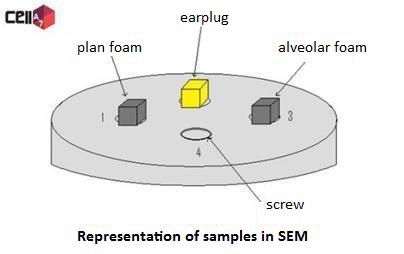

Samples are put on screws which enable electrical contact in microscope. Number one is put at the bottom to keep the same point of reference for each observation.

However, SEM has limits and we must consider that the sample must support a high vacuum and conduct electrons. So, it must be conductor. In our cases, polyurethane foams are not conductor, therefore we need to make plating on our samples to obtain a good quality image.

Samples preparation:

Sample preparation is an important step. We cut out small cubes with a side length of about 3 mm with caution in order to not flatten them.

Samples are carefully put on aluminium conductor platforms thanks to an adhesive tape made by an adhesive polymer and carbon which are also conductor. We must not touch them to do not grease them; it is why we use pliers. Samples have also to be numbered to have a good traceability.

Then support and samples are put in the chamber of metallizers where a primary vacuum is made. An argon gas (generator of purple plasma) is injected and a second vacuum is made. These several steps enable a good total clean-up of the chamber.

During metallisation, electrons are extracted from a silver plate present in the chamber by the plasma thanks to a potential difference between bottom and ceiling of the chamber. A fine silver coating appears (thickness of one or two silver atoms) on the foam samples.

Two steps of metallisation of one minute each and with a high voltage are made. This treatment is long because of the nature of samples which have an important porosity.

We stop vacuum and samples are prepared for SEM analysis.

The main interest of this metallisation is to make foam samples conductor to observe them under a SEM which seems not possible without this coating. We know that the treatment has been efficient if we can obtain good pictures of samples.